Golfing News & Blog Articles

3D Printed Golf Clubs: A Fad or the Future?

A reader recently asked: “Do you see 3D printed clubs as a fad or the way of the future?” It’s an excellent question about a technology that’s already transforming golf equipment manufacturing.

3D printing in golf clubs isn’t some futuristic concept we’re waiting on – it’s already here and has been for a while. Players like Bryson DeChambeau, Rickie Fowler, Gary Woodland, Kyle Westmoreland, and Max Homa have all put 3D printed clubs in play on Tour. To date, COBRA has 3D printed irons, utility irons, wedges, and putters. And that’s the stuff we know about. I’d bet good money that there are some metalwood prototypes somewhere in COBRA’s R&D department.

Why 3D Printing makes sense for golf clubs

The magic of 3D printing (or additive manufacturing) lies in its fundamental difference from traditional methods. When you forge or mill a clubhead, you start with a big chunk of metal and shape it down – trimming edges, milling pockets, essentially taking away a bunch of material you don’t need until you arrive at your final shape.

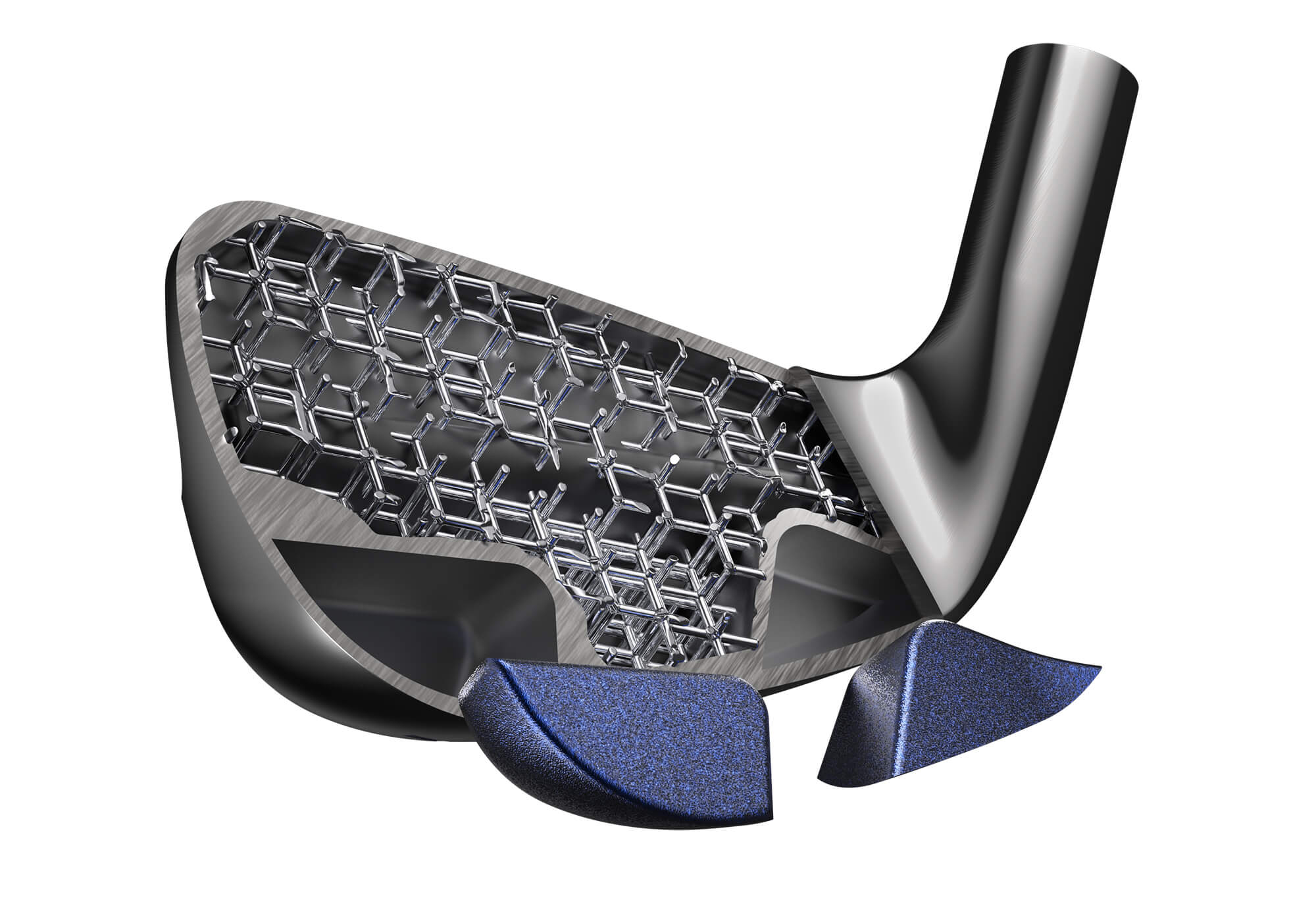

3D printing flips this approach on its head. Instead of removing what you don’t want, you’re only adding what you need – building the club layer by layer from the ground up. This makes creating complex geometries significantly easier and allows designers to avoid having to work around what I suppose qualifies as mandatory weight where it isn’t desirable, instead placing mass only where it benefits performance.

What we’ve seen so far

To date, we’ve seen products like the COBRA 3DP Tour Irons (a full market release of what was the LIMIT3D), which deliver game-improvement-like performance in a compact package typically reserved for better players’ irons. And while that’s cool in and of itself, it’s just the first of what will likely be several 3D printed golf clubs offered to consumers.

COBRA has also produced one-off MB prototypes for Tour players, showcasing its ability to manipulate shape and center of gravity placement for the individual golfer. Through 3D printing, it has become much easier to target individual player needs or change one aspect of a design without having to rework several others.

a cutaway of a COBRA 3D Printed iron

a cutaway of a COBRA 3D Printed iron

What we’ve seen so far primarily falls in the Tour category with Tour-inspired shaping. This begs the question: What happens when you apply these principles to a full-size game improvement head with massive amounts of discretionary weight to move around? The result would likely be something entirely unique.

The possibilities are practically endless, and you can bet we’ll see an expansion of the COBRA 3D Printed iron lineup before the season is over.

What about drivers?

When it comes to metalwoods, everything is about weight management. How many stories have you heard about carbon fiber saving a few grams from the crown?

The ability to reduce structural weight and move it exactly where it provides the most benefit. If a manufacturer can take a significant amount of weight out of the face (without giving most of it back by way of supporting structures) it opens up fascinating design possibilities.

Benefits beyond performance

The advantages of 3D printing extend beyond pure performance:

Precision and repeatability No expensive molds required Significantly reduced cost for one-off production Opens countless doors for customization

Why aren’t there more 3D printed golf clubs?

As with many things, cost remains the biggest obstacle to widespread adoption of 3D printing in golf. The machines required for metal 3D printing aren’t particularly fast nor are they particularly inexpensive. There are substantial costs to scale up production.

As technology evolves and prices come down, expect production to increase.

Finishing costs are also considerable. While not necessarily crucial for functionality (COBRA’s 3D printed club won’t rust), golfers expect clubs to look a certain way, and addressing these aesthetic preferences adds to the final price tag.

At $3,000 for a set of irons, 3D printed clubs remain a premium option. Even if manufacturers could reduce that to $2,000, it’s still a significant investment for most golfers.

COBRA recently released a collection of fully 3D Prinited LIMIT3D putters

COBRA recently released a collection of fully 3D Prinited LIMIT3D putters

That said, other manufacturers are absolutely exploring this space. Callaway talked about printing prototypes to more rapidly confirm (or discard) design concepts during the development of Elyte. There was plenty of chatter about a smaller manufacturer bringing a 3D printed driver to market, although we haven’t heard much about it lately.

So, why haven’t we seen more commercial products?

Patents likely play a role. I’ll leave the interpretation of COBRA’s IP to the experts, but the industry chatter suggests that COBRA’s patents are broad, and while they may face challenges long-term, for now they present an obstacle for competitors looking to commercialize 3D printed clubs.

Notably, while Avoda Golf 3D printed irons for Bryson, what they offer to golfers is produced using conventional manufacturing techniques.

Fad or future?

Bringing us back to our original question, 3D printing in golf clubs isn’t the future – it’s the current reality. While being COBRA-exclusive currently limits its reach, the potential far exceeds any existing manufacturing process.

This technology is absolutely part of golf’s future. It’s here now and not going anywhere. Even if it doesn’t immediately result in more commercial products, expect every manufacturer to employ 3D printing somewhere in their product creation process, with expansion into other categories expected sooner rather than later.

The 3D Printing revolution isn’t coming – it’s already begun.

Got a question?

Got a golf gear question? Ask it in the comment section below. It may be featured in an upcoming story.

The post 3D Printed Golf Clubs: A Fad or the Future? appeared first on MyGolfSpy.