Golfing News & Blog Articles

History’s Mysteries: The Birth of PING’s Color Code System

Welcome back, my friends, to the show that never ends. It’s time for another edition of MyGolfSpy’s History’s Mysteries.

We’re so glad you could attend. Come inside, come inside.

In History’s Mysteries, we take a deep dive into the people, products, companies and events that are woven into the fabric of the game we love. Today’s story focuses not on a product, but on a process introduced in 1972 that lies at the very foundation of the modern golf equipment business.

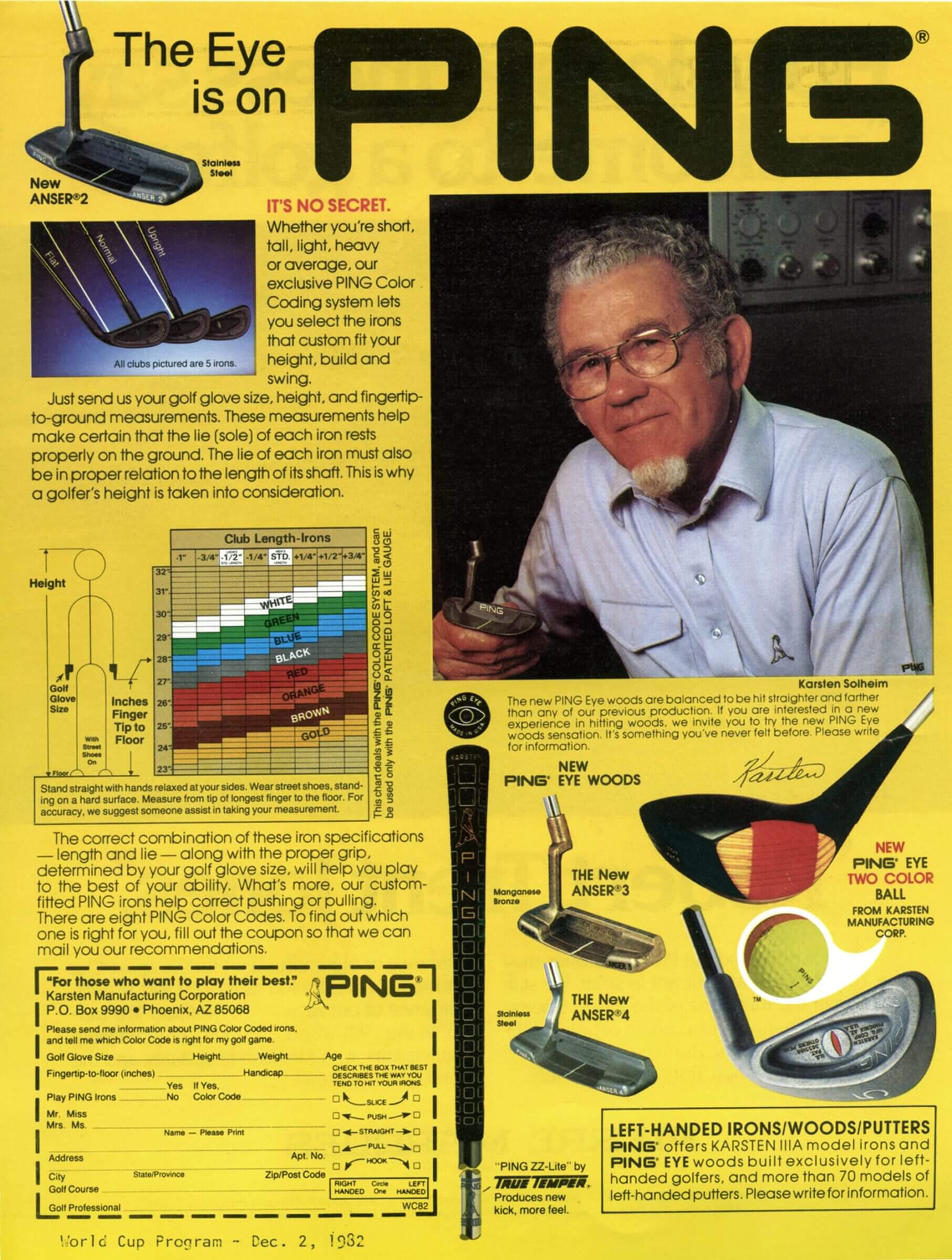

Please join us as we examine the genesis, introduction and evolution of PING’s color coding system. Its introduction in 1972 can truly be considered the birth of modern club fitting and yet another of Karsten Solheim’s contributions to golf as we know it.

History’s Mysteries: The birth of PING’s color code system

Today, custom club fitting is probably about 90 percent science and 10 percent artistry. You walk into a hitting bay and the launch monitor will tell you damn near everything you need to know in seconds. You get carry and total distances and the ingredients behind those numbers. Ball speed? Check. Angle of attack? Check. Face angle and club path to target? Check.

Want to compare different shafts or clubheads? Your fitter has a full array of tools and options to do just that.

However, if you turn the clock back a few decades, fitting was almost entirely an art form. More accurately, it was educated guesswork.

“It used to be just a pro watching you hit a few shots and telling you that you need this or that,” Rob Griffin, PING’s Company Historian, tells MyGolfSpy. “There weren’t a lot of options back then.”

Today, it’s all about options. You can hard step or soft step hundreds of different shafts, and AI apps can fit you for model, length, lie and flex in just a few swings. Back in the day, however, you didn’t even have lie angle options.

“There was no standardized lie angle,” says Griffin. “There was just what different manufacturers considered standard, and they didn’t offer the ability to change it.”

As is the case in so many other areas, it was PING founder Karsten Solheim who found a better way.

The engineer’s mind at work

As we’ve written in this space before, if Karsten Solheim isn’t on your Mount Rushmore of Golf Equipment, you need to reevaluate your decision-making process.

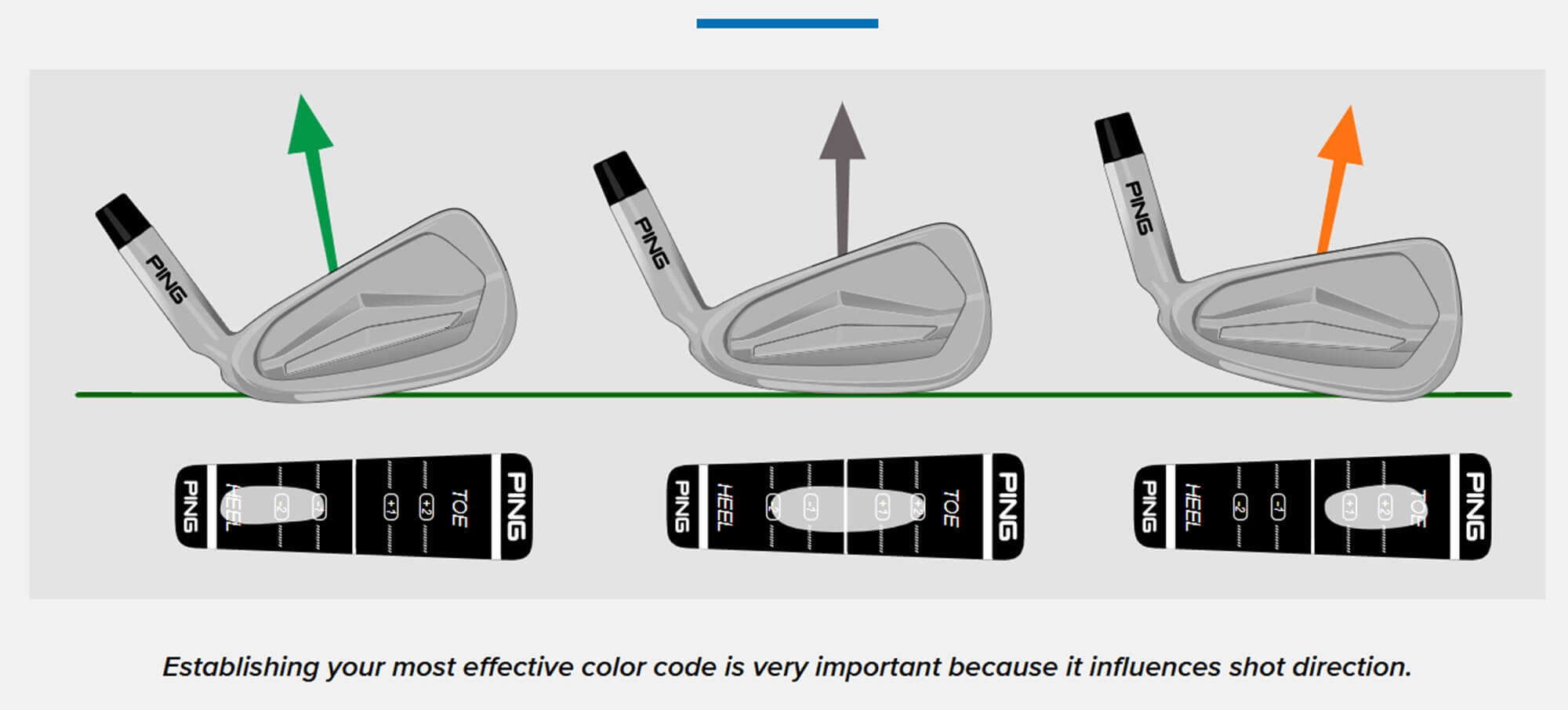

“Karsten realized early on that the way the club hit the ground and the lie angle affected where the ball went,” explains Griffin. “I’m sure there were people who understood that before, but there wasn’t a lot of custom fitting going on. Everyday consumers certainly weren’t getting it.”

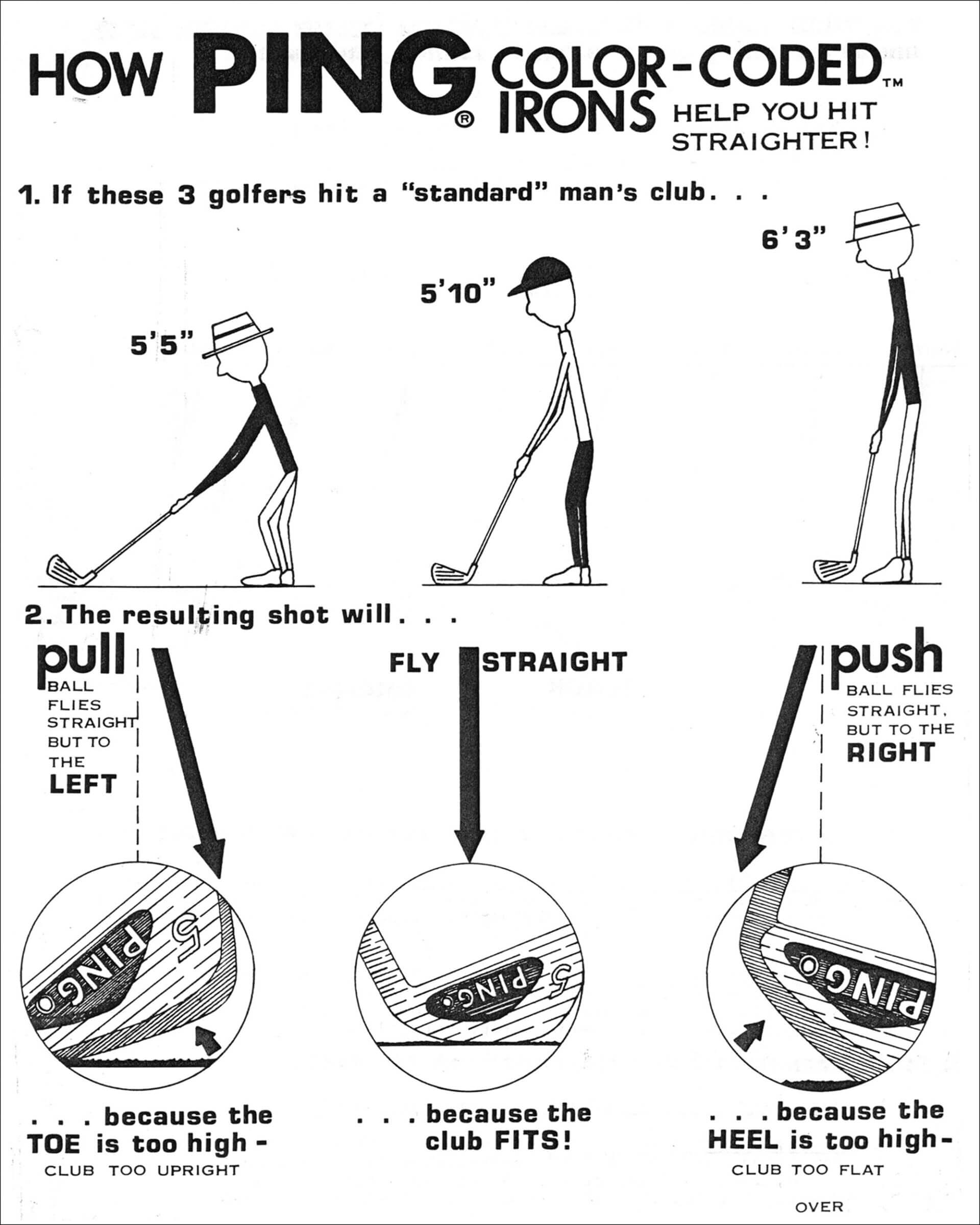

A typical fitting back then was essentially a pro handing you a club to hit. If it was too upright for you, you’d tend to hit it left. Too flat and you’d hit it right. Most golfers didn’t really understand the cause and effect. You’d just keep trying clubs until you found one you could hit straight.

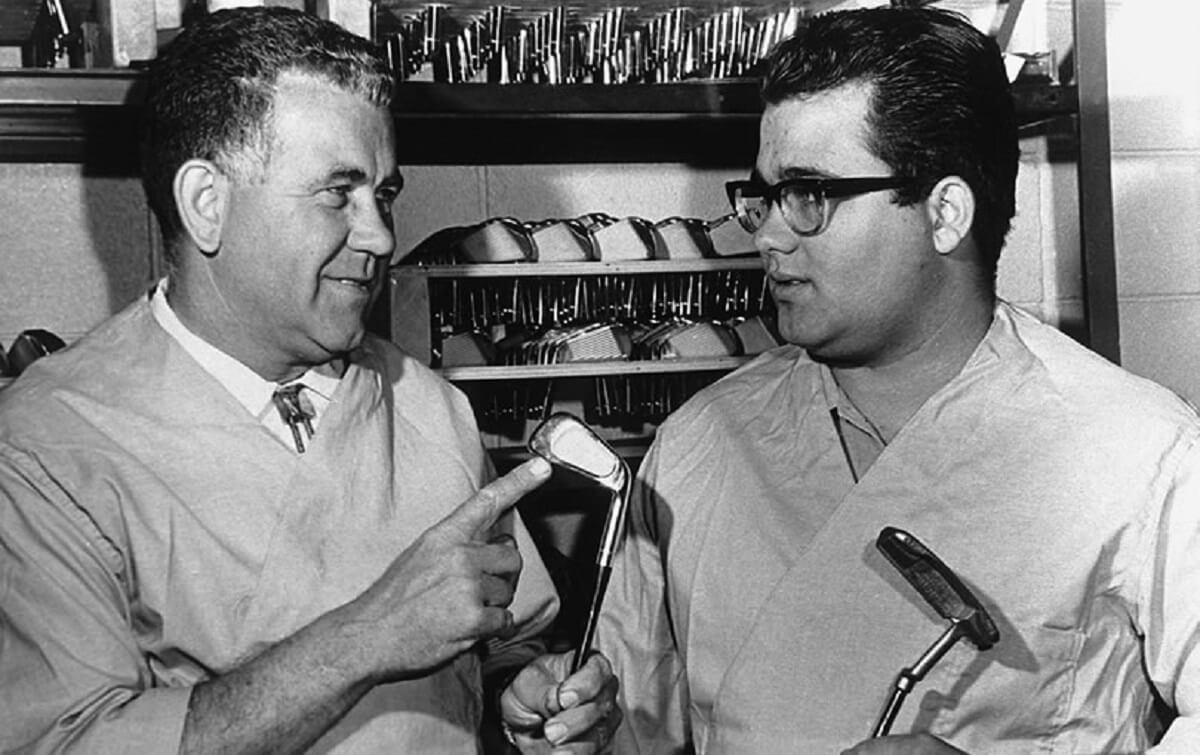

Solheim founded PING in 1959 but was still working out of his garage into the mid-’60s. By then, however, he had developed a reputation among Tour pros as a bit of a “club whisperer.” It was not uncommon for Tour players, when in town for the Phoenix Open, to stop by his house and have him measure and adjust their clubs.

“He’d ask the player which iron they hit best and had the most confidence in,” says Griffin. “If they said the 6-iron, Karsten would bend all the clubs to have the same lie angle as their 6-iron.

“Johnny Miller is one who would come out to the house. Karsten would adjust his set and he’d go out and win the next couple of tournaments.”

Sowing the seeds of dot

These weren’t necessarily PING players who visited Karsten. He’d work on anyone’s clubs. However, both Karsten and Tour golfers realized a yearly visit to check loft and lie wasn’t enough. As was Karsten’s way, once he identified a problem, he’d work on it until he found a solution.

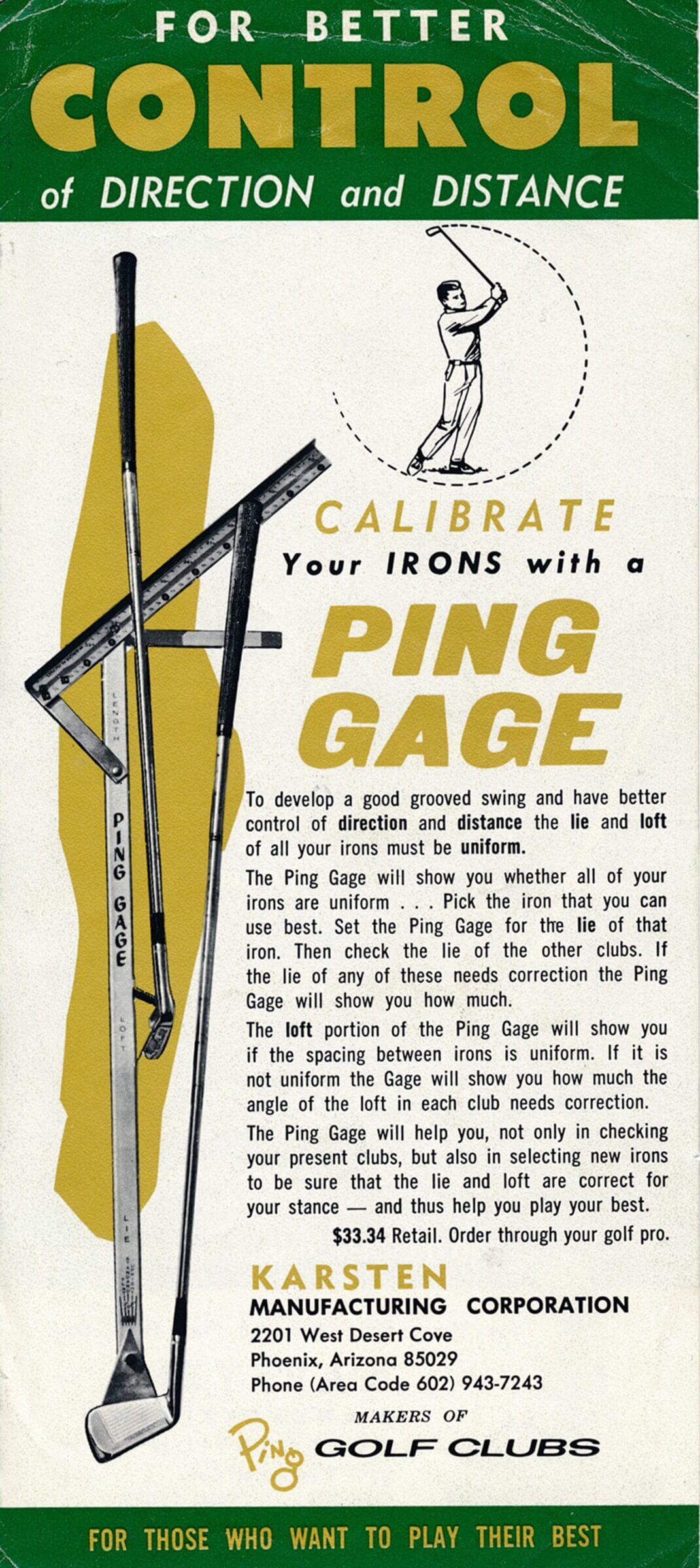

“He didn’t have a Mitchell machine or anything,” says Griffin, as the Mitchell SteelClub® machine wouldn’t be introduced for another 20 years. “He developed his own thing called The Gage.”

The Gage is one of those Karsten inventions that’s lost to history. PING used it to measure and adjust loft and lie for years and it was sold in the PING product catalog.

“Tour players would buy one and keep it in the trunk of their car,” Griffin says. “They could then adjust their clubs themselves when they were out on the road.”

PING introduced its first mass-produced investment-cast irons in 1969. As Karsten knew the proper lie angle was critical to a proper fit, the new K-1 irons had to be malleable enough to bend without breaking.

“We learned to heat treat the heads to make them easier to adjust,” says Griffin. “Without that heat treatment, we couldn’t bend them. They’d just snap.”

The original K-1 irons could be bent from four degrees flat to three degrees upright. That set the stage for Karsten’s next step: developing a repeatable and scalable way to fit more golfers to the right lie angle.

Club fitting for the masses

Karsten certainly wasn’t the only person in golf who knew that lie angle affected ball flight. He was, however, the only one who saw that everyday golfers would benefit from having the correct lie angle. Moreover, he was the one with the necessary creativity and engineering expertise to develop a scalable solution.

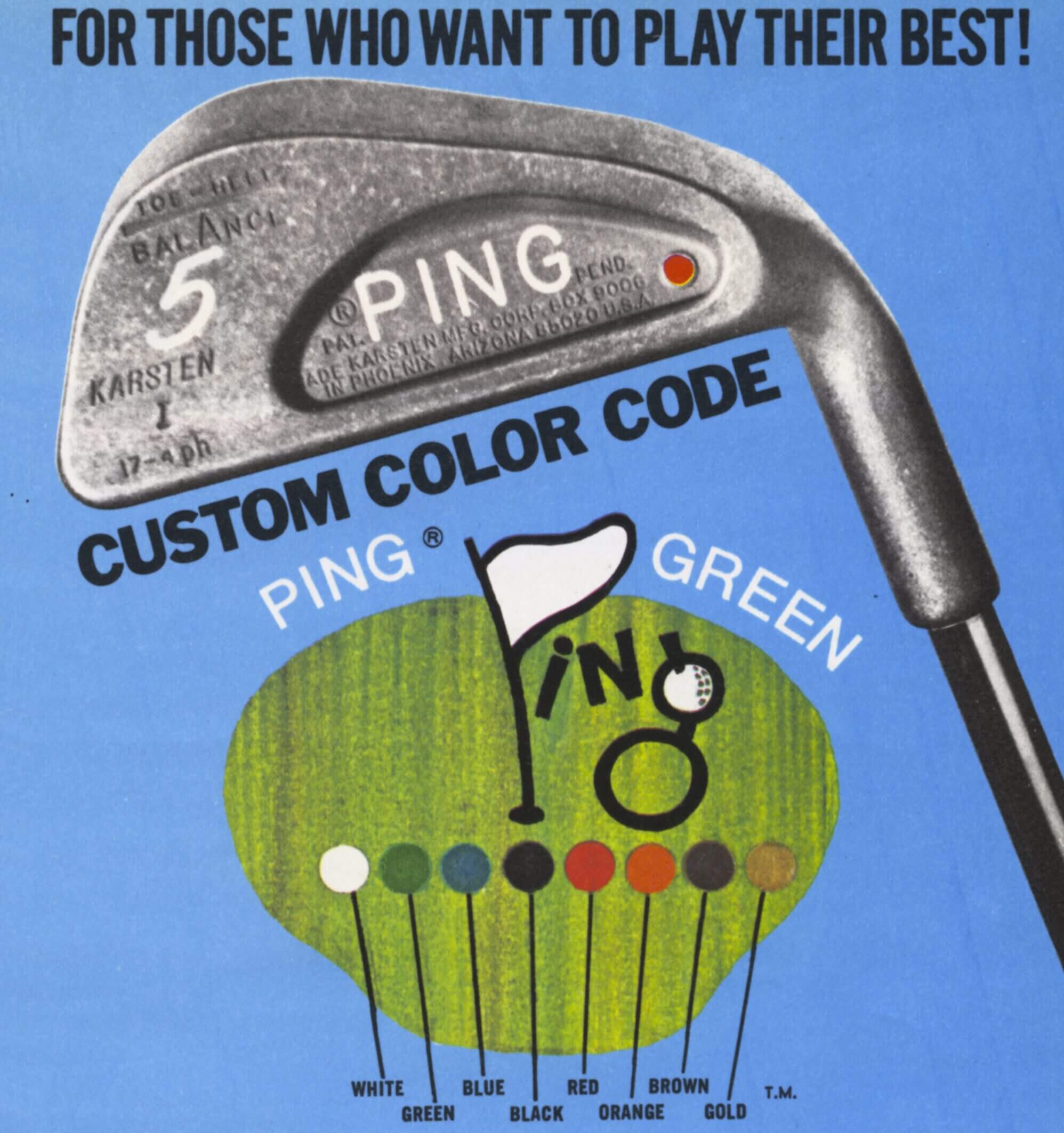

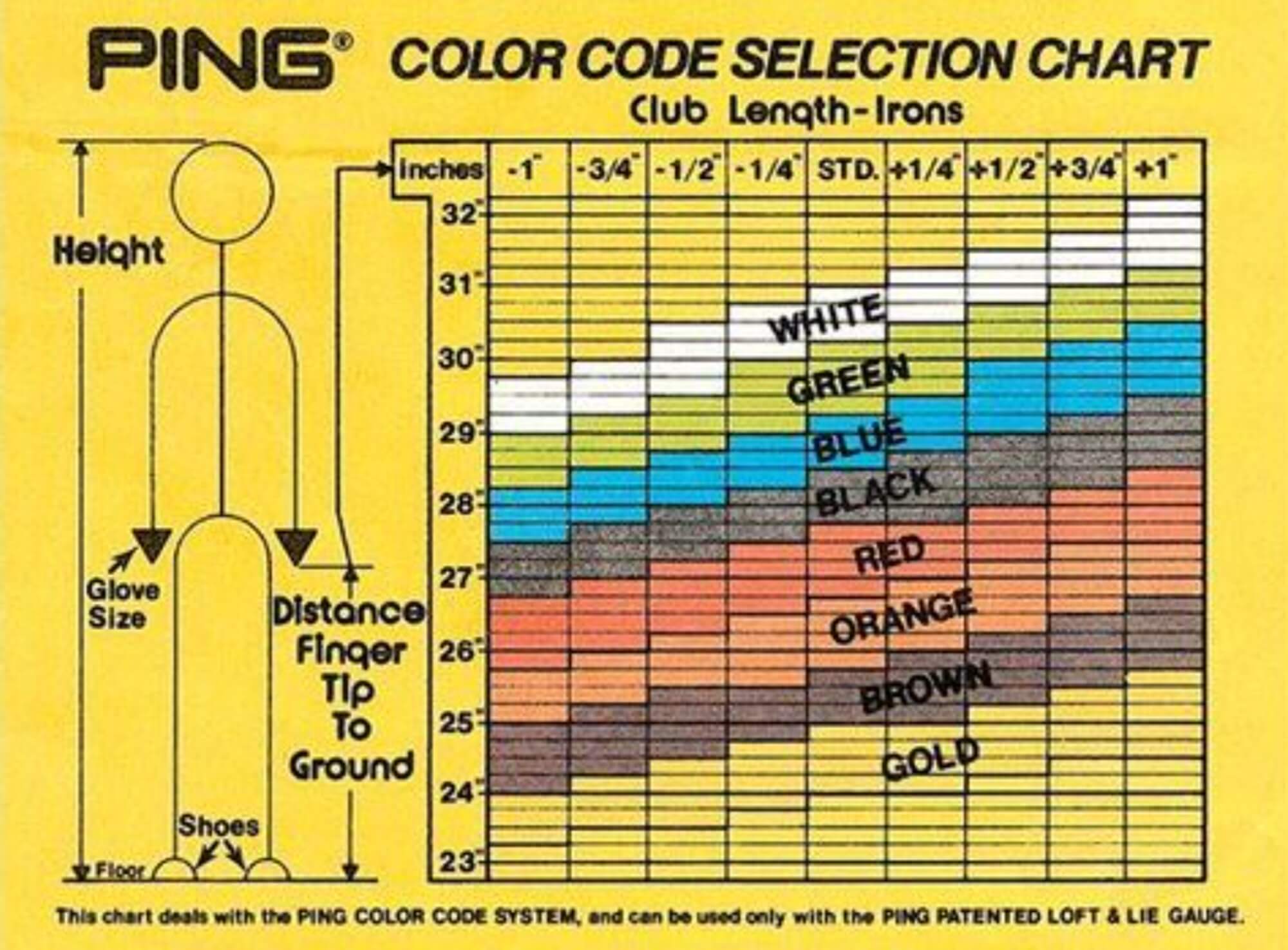

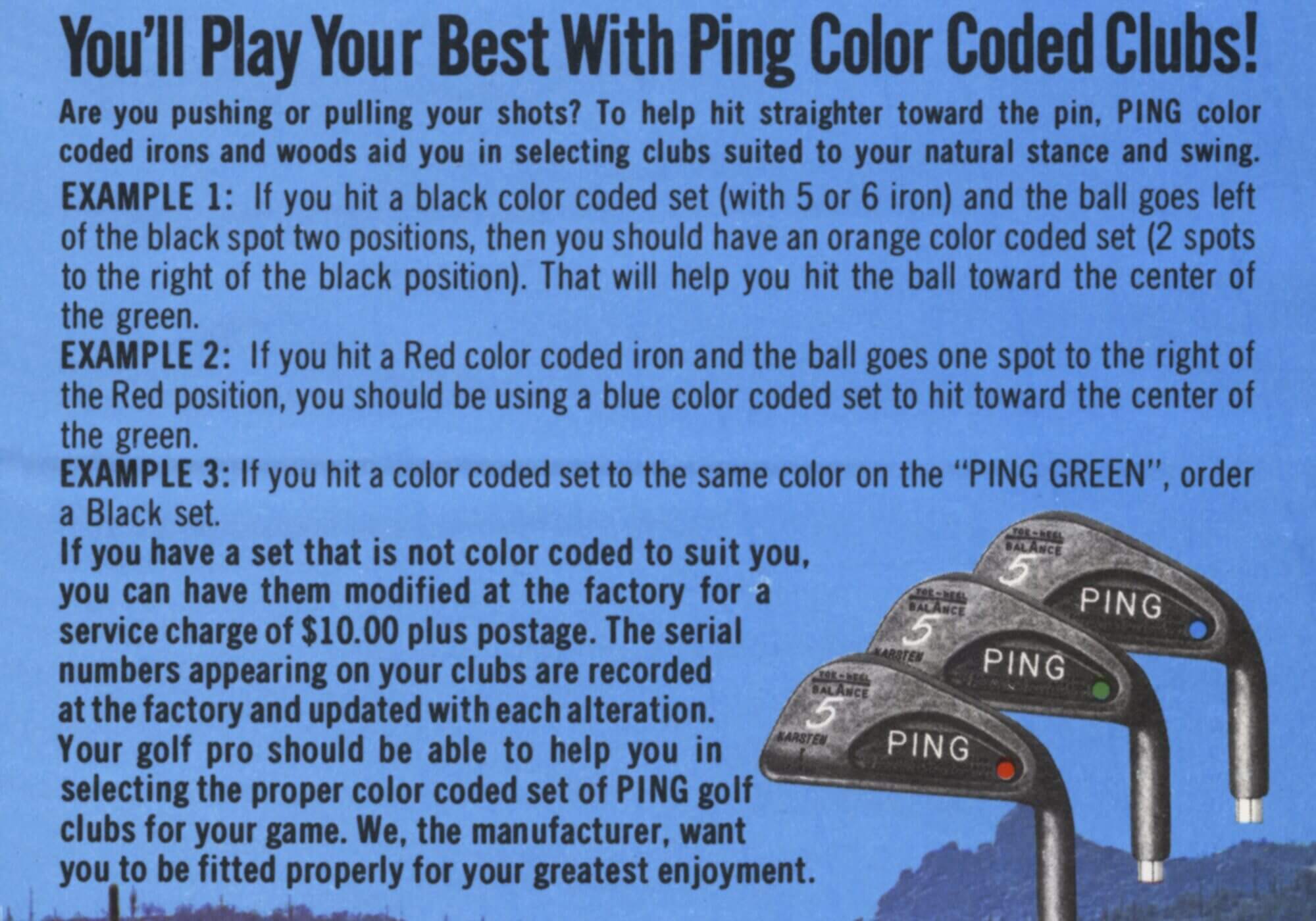

And thus, in 1972, the PING color code “dot” system was born. Karsten based the system on two key criteria: the golfer’s height and fingertip-to-floor measurement (today it’s wrist-to-floor). PING also eliminated “standard” sets from PING’s offering. From that moment on, every PING K-1 iron set would be custom-built to a golfer’s specific lie angle, denoted by the color of the dot. This would be done at no extra charge.

“At first, Karsten would fit people just by looking at their ball flight,” explains Griffin. “But he soon developed this little custom-fitting tool that looked like a football.”

The tool, which was actually a hand-held sliding chart, would slide left or right, depending on which way your shots were flying and by how much you were missing the target. The further you’d slide the tool left or right, you’d find the color that corresponded to your lie angle.

“It changed the golf world because it democratized fitting,” says PING VP of Fitting and Performance Marty Jertson. “It’s a staple, foundational piece that put us on the map. Any good iron or wedge fitting still starts with lie angle.”

In June 1972, PING ran an ad in Golf World featuring its new custom color-coded clubs. PING would include “clip and return” cards in magazines. You’d write in your height and other measurements and PING would send back recommended specs.

The first round of ads generated more than 14,000 responses. The program proved so successful that PING continued it well into the ’90s.

“I’m a red dot, what are you?”

As important as those little colored dots were to fitting, don’t underestimate how powerful a branding tool they became. It wasn’t long before PING users identified themselves as a “red dot guy”, an “orange dot guy” or whatever.

For the first time, a regular Joe could show you his colored dot and say, “These clubs were built for me.” It’s the kind of brand identity OEMs pay millions for today.

“Karsten made it easy for consumers to understand the importance of lie angle,” says Griffin. “He created and delivered a simple, logical story with an obvious benefit to golfers that was easy to understand and that no one else was telling.”

The color code chart Karsten created is still central to PING fittings today. If you ever visit the PING Proving Grounds in Scottsdale, the first thing they do is take height and wrist-to-floor measurements and reference the chart to get you started.

“We have better, more nuanced, more nitty-gritty numerical, launch-monitor driven tools to get you even further into the fitting pyramid,” says Jertson. “But we still start every fitting with the color code chart.

“If you’ve never picked up a club before, you could 100 percent use the chart as a starting point for length and lie.”

Days of future past: Color codes today

Today, PING’s color code system isn’t just a fitting tool. According to Jertson, hitting the full color palette is an R&D mandate.

“We’re not going to make an iron we can’t adjust to those specs,” he explains. “We might come up with something that will give us more ball speed or do something really exotic. But if it won’t fit those lie angles, we can’t pass it to the customer.”

Today, PING’s color code chart runs from five degrees upright to four degrees flat. As you’d imagine, that creates some metallurgical challenges. The iron needs to be strong and durable while remaining soft enough to bend up to 10 degrees. Those are two things that fight each other.

“It’s the structural engineering of the hosel and the geometry of the notches,” says Jertson. “How we clamp them for bending, the materials of the clamp, what pressure we use, it all matters.

“Then there’s how we heat treat the alloys to be able to control the bending and the metallurgical properties that allow us to achieve that.”

The next step, of course, is to take the color code system into the digital world. Most online club-fitting apps will ask for your height and wrist-to-floor measurements. That alone will fit at least 75 percent of golfers into suitable club specs. Artificial intelligence, however, is opening up even more opportunities.

“We’ve built an entire suite of amazing fitting tools,” says Jertson. “Some of them ingest launch monitor data and can get you to the nearest perfect spin rate and ideal distance gapping.

“We’re still committed to the club color code charts. That’s still our foundation but today we have the technology and the precision to give the modern golfer what they need to help them play their best.”

What would Karsten think?

It’s no exaggeration to say Karsten Solheim started custom fitting as we know it today. That’s not to say we wouldn’t be where we are now without his contributions, but he was certainly there at Ground Zero.

Karsten made sure that little football-looking device got out to pro shops. PING aggressively advertised the importance of lie angle fitting in its magazine ads while offering golfers something they never had access to before: an actual custom fitting. It certainly wasn’t the same as today’s custom fitting, but for 1972, it was a major leap forward.

As with every conversation I have with Griffin, I had to ask: What would Kasten have to say about the level of fitting in 2025?

“I think he’d say there’s never enough data. You know, we were the first golf manufacturer to have a high-speed camera in the mid-‘80s. He wanted to measure things and see what was going on. We could measure spin rate and see what was happening to the shaft at impact, how it was bending, how it oscillated.”

And what would Karsten do if he got his hands on a Trackman?

“My guess is inside half an hour he’d design a better one.”

History’s Mysteries: PING and a color-coded postscript

It’s also no exaggeration to say Karsten Solheim taught the golf industry how to build a modern golf club. No one was paying much attention to lie angle in 1972, and certainly no one was trying to bring custom fitting to the masses. He had the mind of an engineer but let’s not forget that he also had a good bit of salesman in him.

“A lot of us don’t fully appreciate Karsten’s marketing ability and his ability to explain things in an ad or a picture,” says Griffin. “That’s his gift: explaining very technical things and very scientific ideas in a way that most of us can grasp.”

Fitting is the next frontier in the golf industry. It’s the one place where you can actually achieve substantive performance gains. Many OEMs are leveraging AI to make the process faster but Jertson, echoing Karsten’s thoughts, says there’s never enough data.

“We can do a great job fitting you for the swing you have that day. But how much better of a job could we do if we added your tendencies and on-course play into the fitting process? We’ve built some great tools to do that.

“The more data you have, the more you can paint a picture on a continuous, transparent basis.”

“Karsten always said his No. 1 goal was to make the game easier for people to play,” adds Griffin. “I never heard him talk about how many clubs we sold or anything like that. He just wanted to make the game more enjoyable for people.

“As he would say, you want the club to fit the golfer, not the other way around.”

The post History’s Mysteries: The Birth of PING’s Color Code System appeared first on MyGolfSpy.